When homeowners choose new windows, performance is often judged by what is visible: the frame finish, the glazing, or how smoothly the sash opens and closes. Yet the real determinants of quality lie much deeper in the manufacturing process. Precision engineering, material selection, testing protocols and quality control all play a decisive role in how a window performs over decades.

Let’s have a look at a full window manufacturing journey, expanding on the technical steps involved and explaining why each stage matters. While the principles apply across the industry, we also reference how Fairco integrates these processes into its own manufacturing and specification standards.

Design and performance specification

Every high‑quality window begins with detailed design and performance targets. At this stage, manufacturers define thermal performance requirements, structural strength, weather resistance, acoustic control and security standards. These targets are informed by Irish and EU regulations, including Part L of the Building Regulations and relevant EN standards.

Design decisions made here influence:

- Frame depth and chamber design for insulation

- Compatibility with double or triple glazing

- Hardware integration and load‑bearing capacity

- Compliance with security standards such as PAS 24 where required

At Fairco, window systems are engineered as complete assemblies rather than isolated components. This ensures that frames, glazing, seals and hardware work together as a single thermal and structural system.

Profile extrusion and material selection

For uPVC and aluminium windows, frame profiles are produced through extrusion. This process involves heating raw material and forcing it through precision dies to create consistent cross‑sections. Accuracy at this stage is critical, as even small dimensional deviations can affect air tightness, glazing fit and long‑term durability.

Modern multi‑chamber uPVC profiles are designed to trap air, reducing heat transfer through the frame. Aluminium systems, by contrast, rely on advanced thermal break technology, where low‑conductivity materials separate internal and external sections of the frame.

Fairco specifies profile systems that balance strength, insulation and longevity, with options tailored for uPVC ranges such as Fairco Performance uPVC and thermally broken Aluminium systems used across sliding and fixed glazing solutions.

Reinforcement and structural integrity

Once profiles are produced, reinforcement is added where required. This is particularly important for larger openings, sliding doors and windows exposed to higher wind loads. Reinforcements are typically galvanised steel or engineered aluminium inserts fitted within the profile chambers.

Structural reinforcement helps prevent:

- Frame deflection under load

- Operational issues such as sash drop or misalignment

- Reduced sealing performance over time

Correct reinforcement design is essential for compliance with structural testing under EN 14351‑1 and for ensuring consistent performance across the product lifecycle.

Cutting, machining and welding

Profiles are cut to precise dimensions using CNC‑controlled machinery. Mitre joints are prepared for welding or mechanical joining, depending on the system type. Accuracy at this stage directly affects squareness, weather tightness and visual finish.

For uPVC windows, corners are heat‑welded to form strong, airtight joints. Excess material is then cleaned and finished to ensure a smooth, consistent appearance. Aluminium systems typically use mechanical corner cleats combined with crimping or bonding for strength.

Fairco places particular emphasis on tight manufacturing tolerances, as this supports improved gasket compression and consistent thermal performance once installed.

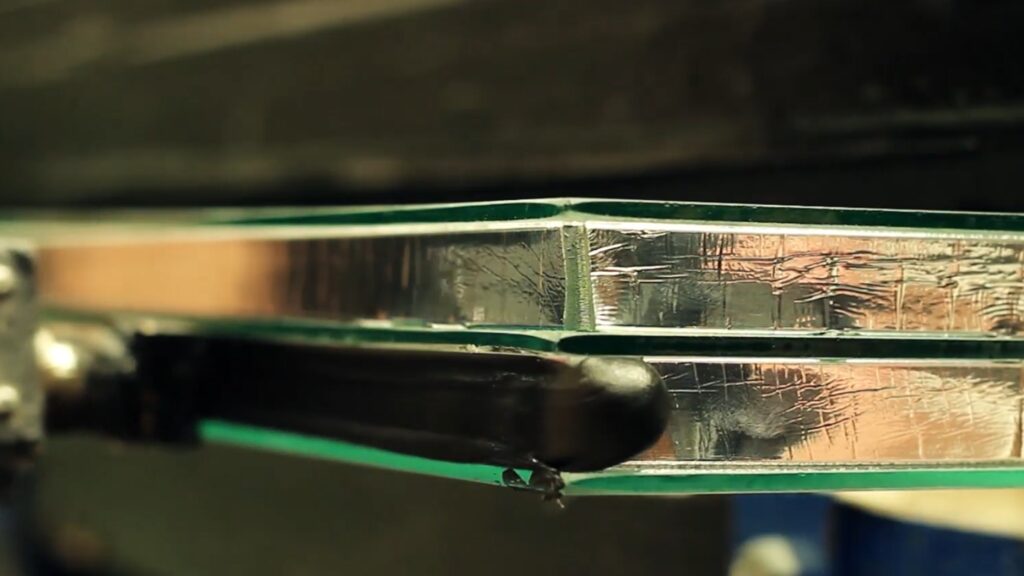

Glazing specification and installation

Glazing is one of the most critical contributors to window performance. Units are specified based on thermal, acoustic and solar control requirements. Typical specifications may include low‑emissivity coatings, argon gas filling and warm‑edge spacers to reduce heat loss at the perimeter.

Correct glazing installation is essential. This includes:

- Accurate glazing packers to support the unit and prevent stress

- Continuous perimeter sealing to maintain airtightness

- Compatibility between glazing thickness and frame design

Fairco systems are designed to accommodate high‑performance double and triple-glazing, supporting low U‑values without compromising frame stability.

Hardware and operating mechanisms

Locks, hinges and opening mechanisms are installed after glazing. These components must be matched to sash size and weight to ensure smooth operation and long‑term reliability. Poor hardware selection is a common cause of operational failure, even in otherwise well‑manufactured windows.

Quality hardware contributes to:

- Enhanced security and resistance to forced entry

- Ease of use and ergonomic performance

- Maintained alignment over repeated use

Fairco specifies tested hardware systems compatible with its window ranges, ensuring performance consistency across residential and architectural applications.

Sealing, gaskets and weather performance

Multiple sealing layers are fitted to prevent air and water ingress. Modern window systems typically use co‑extruded or replaceable EPDM gaskets designed to remain flexible over time. The positioning and compression of these seals play a key role in achieving airtightness targets.

Effective sealing supports:

- Reduced draughts and heat loss

- Improved acoustic insulation

- Protection against wind‑driven rain

Quality control and testing

Before leaving the factory, windows undergo a series of checks. These include dimensional inspections, visual finish checks and functional testing of opening elements. Many systems are also independently tested for air permeability, water tightness and wind resistance.

At Fairco, quality control is integrated throughout the manufacturing process rather than treated as a final step. This reduces the risk of defects and supports consistent performance across large production runs.

Why manufacturing detail matters for homeowners

For homeowners, the manufacturing process may be invisible, but its impact is felt every day. Well‑manufactured windows deliver better thermal comfort, lower energy bills, quieter interiors and fewer maintenance issues over time.

Understanding how windows are made helps homeowners make informed decisions, moving beyond surface appearance to focus on long‑term performance and reliability.

Taking the next step

If you are planning a window or door upgrade, exploring how products are designed and manufactured is a valuable first step. Fairco’s window systems are engineered with performance, compliance and durability in mind.

Explore our window ranges or consult our design team to discuss the right solution for your home.